How To Choose The Right Stainless Steel Pipe, Fittings, And Adapters?

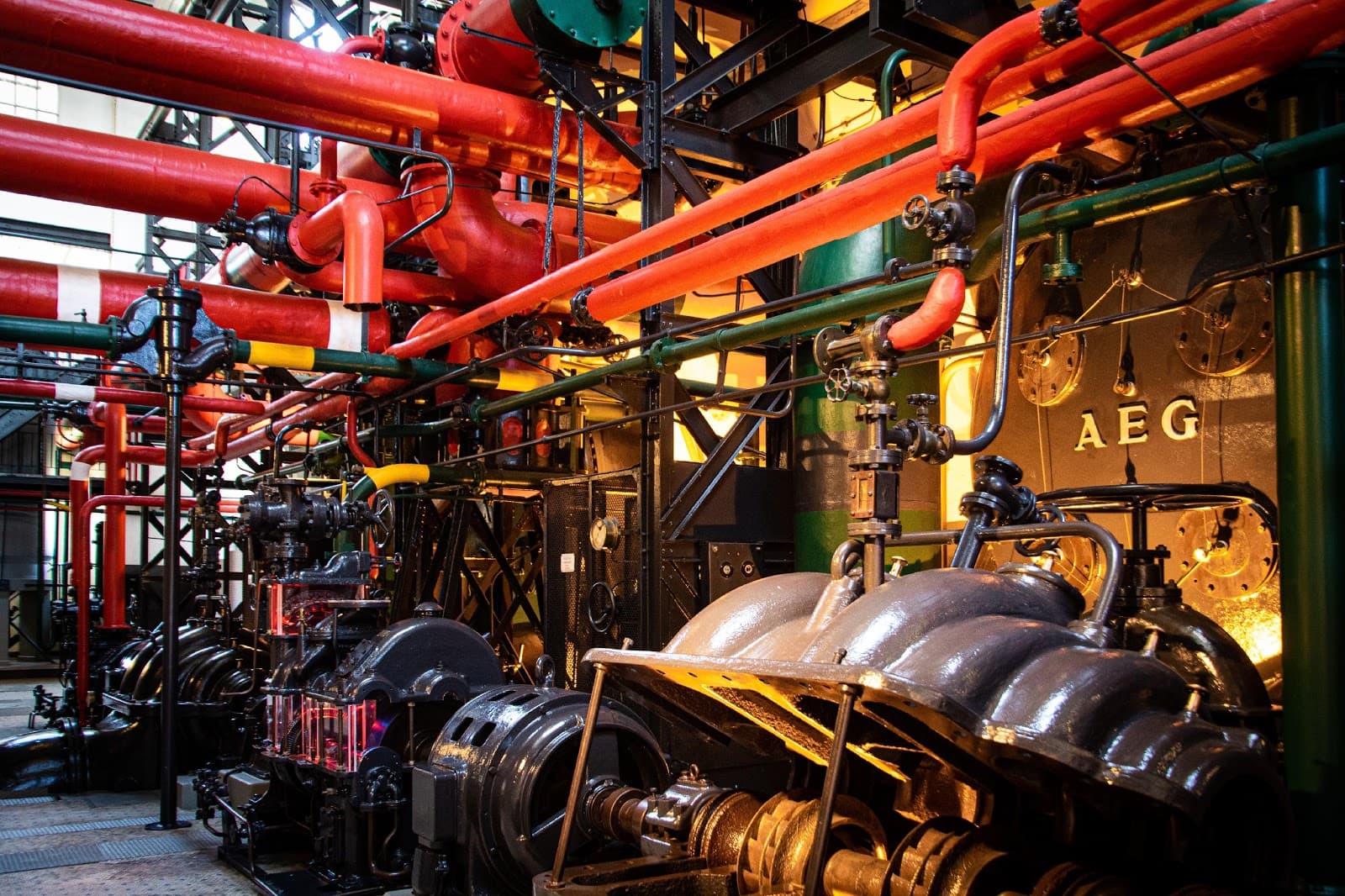

Image Description: An image showing an industrial machine with a network of stainless steel pipes fittings and adapters

In hydraulic systems it’s imperative that you choose the same material types across all components. You also need to make sure that all the components are fluid compatible and can withstand the working pressure.

When it comes to designing the plumbing fluid conveyance system, several design considerations need to be accounted for beforehand. These factors influence the operation, maintainability, and possible downtimes of the system. Most medium to high-pressure systems rely on stainless steel piping, fittings, and adapters. How do you select the right part for the job? We explore the selection process while keeping in mind the factors that go into planning a plumbing system.

Choosing the Right Stainless Steel Pipe

Piping is a major component in processing plants like refineries, power plants, and chemical industries. It is imperative that the right size is chosen for the job. Knowing the pipe’s internal diameter helps you determine the fluid capacity and flow rate of the media carried for the process. Nominal pipe sizes (NPS) identify pipes’ outer diameter. Subtracting the internal diameter from the outer gives you an indication of the wall thickness (the schedule), which becomes important when pressure considerations come into play.

Material

Stainless steel pipes are available in different grades of steel. The one you select depends on your needs. The chemical properties of the fluid the pipes will carry may not be compatible with stainless steel piping and may corrode it from the inside. Similarly, the external environment may not favor the use of stainless steel pipes. In offshore environments, chloride salts seek to threaten the integrity of piping; hence, you may require 316 stainless steel piping as opposed to the more common 304 grade. A cost-benefit analysis may even allow you to use 304 steel, given that you apply necessary corrosion prevention methods, like painting or sacrificial coating on the pipe surface.

Seamless or Welded

Pipes are constructed via two methods. The first is seamless, whereby an ingot is pressed to a cylindrical shape after hot extrusion. In contrast, welded piping is rolled into a cylindrical shape and welded at the seams to make a hollow pipe. Welded piping has its merits when it comes to cost, durability, and availability. However, seamless piping is much more corrosion resistant and can withstand higher working pressure.

Choosing the Right Fittings and Adapters

Fittings and adapters are often referred to interchangeably with each other; however, their functions are different. Fittings attach piping to other plumbing components, like pumps, valves, flanges, hoses, etc. On the other hand, adapters are normally used to connect piping to other pipes or interchange the thread standard, from JIC to NPT, AN, Komatsu, NPS, etc.

Like the piping needs to be fluid compatible, fittings and adapters need to exhibit the same compatibility. Otherwise, fluid leaks and ruptures may become a common occurrence.

Make sure that you use the correct fitting for the job. It must be the same material type as the component it’s connecting to; otherwise, threads may break due to differences in hardness and expansion rates.

Speaking of threads, they must comply with the same standards. A male JIC connects to a female JIC component. Threading standards are different depending on where you operate; they may be tapered or straight, have different flare angles and sizes.